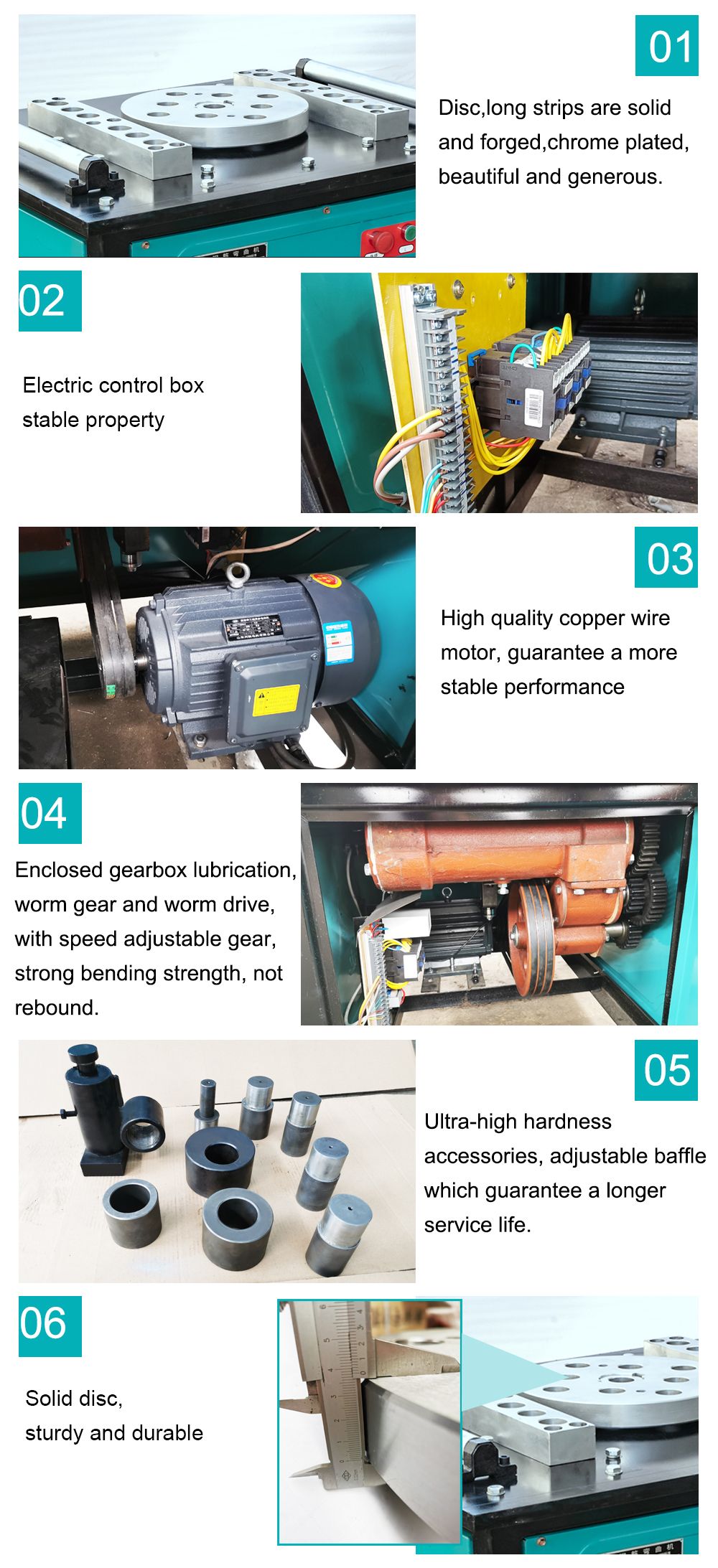

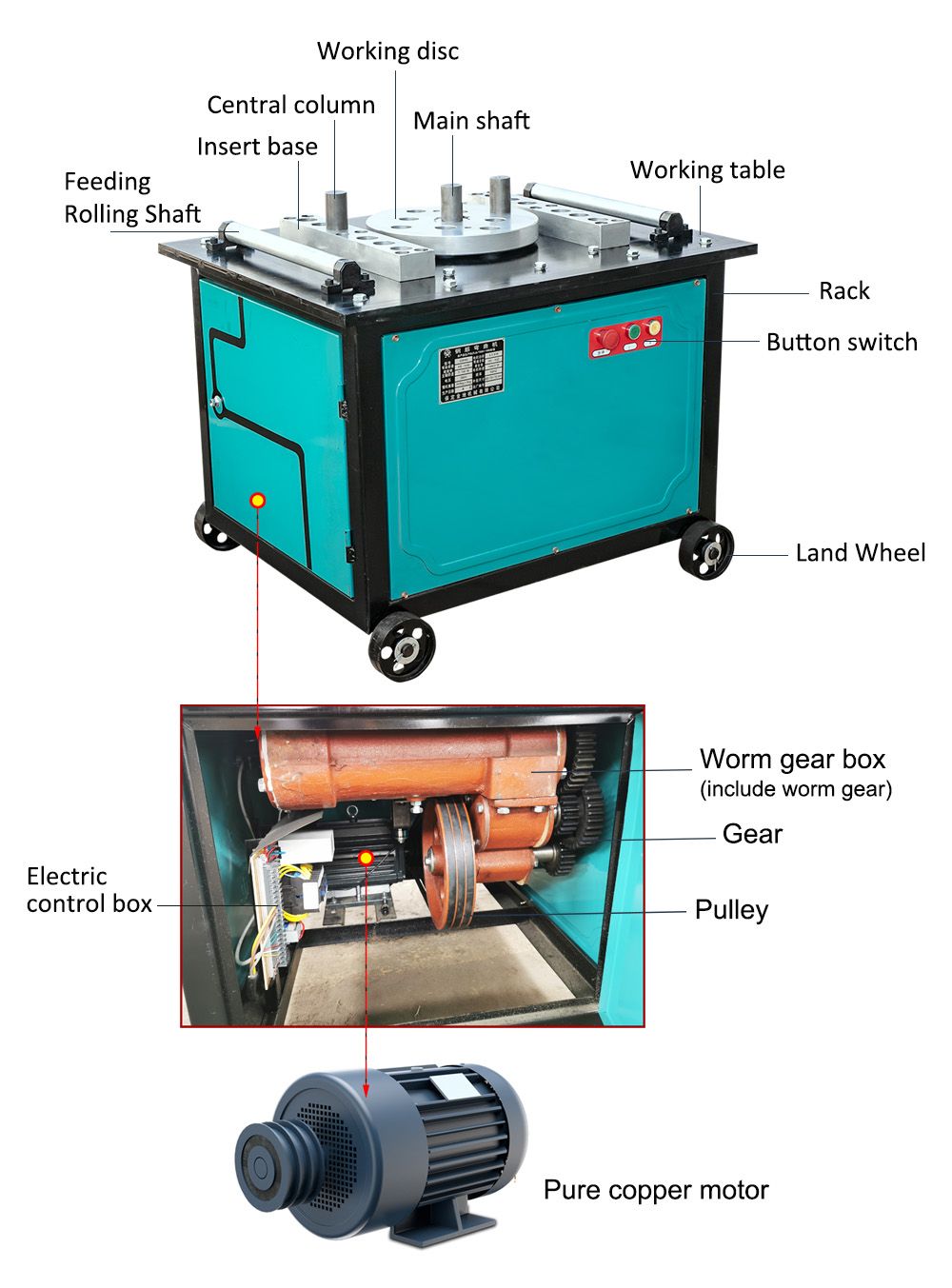

GW40/GW50 REBAR BENDING MACHINE has reasonable design, simple structure and can bend steel rod diameter to any required shape applying to bridge, tunnel and many construction projects. Main Features 1. Simple operation, safe and durable, high quality copper wire motor, guarantee a more stable performance. 2.Fully enclosed gearbox lubrication, worm gear and worm drive, with speed adjustable gear, strong bending strength, not rebound. 3.ultra-high hardened accessories, adjustable baffle which guarantee a longer service life. 4.Machine surface adopts plastic-spray treatment; Accessories like long strips and disc are solid, forged, and chrome plated, so they are beautiful and generous. 5. Specially use thickened steel plate, high rigid disc and bar iron, high power medium speed national standard high quality electronic motor, guarantee a more stable performance.

GW40/GW50 REBAR BENDING MACHINE has reasonable design, simple structure and can bend steel rod diameter to any required shape applying to bridge, tunnel and many construction projects. Main Features 1. Simple operation, safe and durable, high quality copper wire motor, guarantee a more stable performance. 2.Fully enclosed gearbox lubrication, worm gear and worm drive, with speed adjustable gear, strong bending strength, not rebound. 3.ultra-high hardened accessories, adjustable baffle which guarantee a longer service life. 4.Machine surface adopts plastic-spray treatment; Accessories like long strips and disc are solid, forged, and chrome plated, so they are beautiful and generous. 5. Specially use thickened steel plate, high rigid disc and bar iron, high power medium speed national standard high quality electronic motor, guarantee a more stable performance. | Model | GW40 | GW50 |

| Voltage | 3-380V 50HZ | 3-380V 50HZ |

| Motor Power | 3.0KW | 4.0KW |

| Motor Speed | 1440r/min | 1440r/min |

| Rebar Bending Diameter Scope | Common Carbon Steel≤40mm | Common Carbon Steel≤50mm |

| Grade Ⅲ Deformed Bar≤32mm | Grade Ⅲ Deformed Bar≤40mm | |

| Working Plate Diameter | 350mm | 400mm |

| Spindle Speed | 7r (14r)/min | 7r (14r)/min |

| Weight | 345kg±5kg | 380kg±5kg |

| Dimension | 930*770*740mm | 1040*800*770mm |

Spare Parts:

| Spare Parts | Spectification(mm) | Main Function |

| Blocking Rack | Ø54mmØ43mm | Adjust bending time gap according todifferent diameter rebar |

| Eccentric SleeveColumn Sleeve | Eccentric sleeve Ø108(Ø118)mmColumn sleeve 1 Ø96mmColumn sleeve 2 Ø77mm Column sleeve 3 Ø63mm | Adjust rebar gap when bending differentdiameter rebar |

| Central Column/Blocking Column | Central Column Ø65(Ø30)mmBlocking Column 1 Ø43(Ø54)mmBlocking Column 2 Ø26 mm Blocking Column 3 Ø30 mm | Ward rebar when bending rebar |