Established in 2002, Baoding Jindi Machinery Co., Ltd. has grown into a reputable company engaged in the research, development, sale, and service of rebar couplers, rebar thread rolling machines, rebar bending machines, rebar cutting machines, rebar arc bending machines, hydraulic rebar straightening and cutting machines, and more. The company has focused on providing high-quality, innovative solutions to the construction industry, and their rebar couplers have been highly regarded by customers worldwide.

Lapped joints have been a traditional method of connecting reinforcement bars for decades. This method involves overlapping two bars and then tying them together with wire. While it has been the go-to method for years, lapping is not without its problems. Lapped joints have been known to cause congestion within the concrete, which can create durability issues. Additionally, lapped joints can impede the flow of concrete during placement, which can inhibit the integrity of the structure.

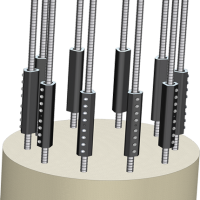

Rebar couplers, on the other hand, are designed to connect two steel bars without lapping or welding. The installation process is simple and straightforward, and it eliminates the need for specialized labor or tools. In addition, rebar couplers provide the benefit of reducing congestion within the concrete, which helps to create stronger, more resilient structures.

One of the most significant benefits of using rebar couplers is the potential for cost savings. By eliminating the need for lapping, time-consuming wire-tying, and the use of additional reinforcement bars, project costs can be significantly reduced. This is especially true in situations where lapping joints are required to be longer, such as in building columns or walls.

Baoding Jindi Machinery Co., Ltd. offers a range of rebar coupler products to suit different project requirements. Their products are designed to be adaptable to a wide variety of construction projects, and they come in different sizes and styles to suit different reinforcement bars. The company has a team of experts who are always on hand to offer advice and support to customers, ensuring that their rebar couplers are correctly installed and meet project specifications.

Another advantage of using rebar couplers is their ability to improve project efficiency. The installation process is quick and straightforward, which means that construction timelines are accelerated. Moreover, rebar couplers offer greater flexibility in the design of the structure, allowing for greater customization of reinforcement placement. This, in turn, can lead to increased efficiency and less need for alteration or rework on the project site.

In conclusion, the use of rebar couplers has become increasingly popular in recent years, offering a cost-effective, efficient, and customizable alternative to lapped joint reinforcement methods. And, Baoding Jindi Machinery Co., Ltd. has played a significant role in the development and manufacturing of these products. By partnering with a reputable company like Baoding Jindi Machinery Co., Ltd., construction professionals can ensure that they are using products of the highest quality that are specifically designed to meet their project requirements.